Chinese wholesale Roll Forming Machinery - HJ-CPX400 Spring roll sheet production line – Hanjue Precision

Chinese wholesale Roll Forming Machinery - HJ-CPX400 Spring roll sheet production line – Hanjue Precision Detail:

|

Product |

Technical Instruction |

|

Spring roll sheet making machine (春卷制皮机) |

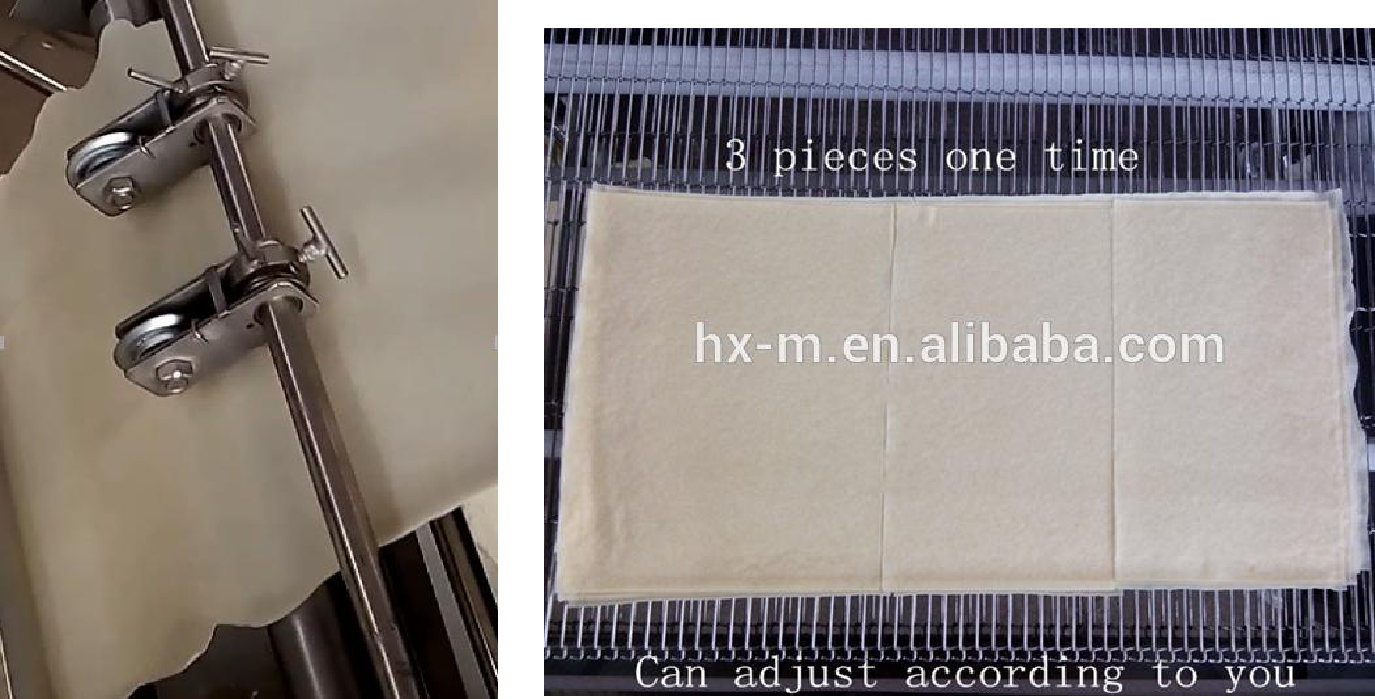

1. Model: HJ-CPX400-62. Sheet width: 375-400mm

3. Sheet thickness: 0.3~2mm 4. Heating drum diameter: 600mm 5. Power: 24KW, 380V 3 phases (add transformer to 110V) 6. Heating mode: heating plates 7. Configuration: ①sheet making machine ②cooling conveyor belt ③cutting machine (adjustable) ④counter (adjustable) ⑤delivery arrangement machine |

1.Main parts

Drum, Cooling Conveyor, Cutter, Array equipment.

Add wheel cutter on machine to change the skin of width and capacity.

Counter

2.. HJ-CPX400 Instruction:

- The main device equipped on this machine:

Wrapper making machine

Vertical cutting device

Cooling conveyor belt

Cutting machine

Conveyor arranging machine

- Function:

The production line may manufacturer thickness 0.3-2 millimeter spring roll skin, the curry cutide, the egg skin, and may manufacturer other laminated food, suits in the food products factory, the hotel, the fast-food restaurant and so on.

- Principle and process:

Principle: firstly, make the liquid according to the liquid manufacturer craft; after the liquid is heated and roasted by the round heating roasting, it becomes the fixed thickness the spring roll skin or other laminated food.

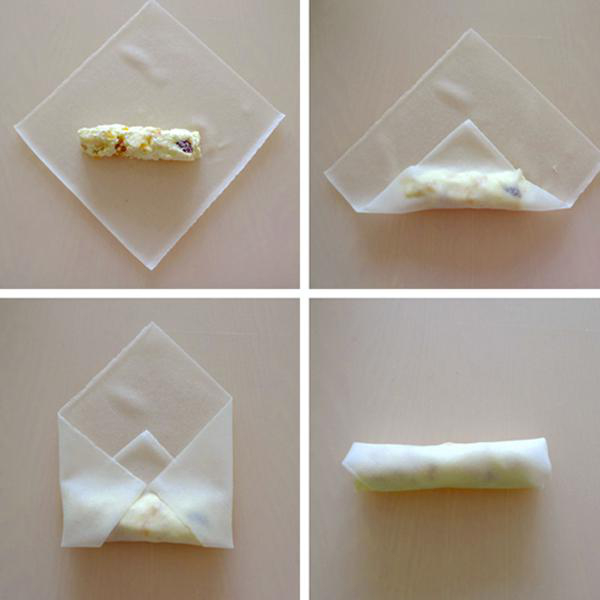

Process: Firstly, put the prepared flour batter into barrel ; secondly, start the thick liquid pump to deliver the surface thick to the spray nozzle place when the round heating roasts after 160℃; then operate the coupling operating lever, that causes the surface thick liquid adherency to roast the round circular arc surface, along with roasts when the wheel has revolved 270-300 degrees angles, the surface thick liquid curing, automatically separate with roasts the whee, so forms the fixed thickness the spring roll skin, after the cutting off machine, become the block, then folds for the sale, or curls a package of spring roll immediately.

3. Can adjust different size, shape:

Howtomakespringroll:

HowtomakeSamosa:

Welcome to our factory to test this machine by yourself !!!

Product detail pictures:

Related Product Guide:

Cricut Cake Machine – How to Turn Edible Cake Decorations Into Cash

Choosing the Best Cake Mixer Machine

Normally customer-oriented, and it's our ultimate concentrate on for being not only one of the most dependable, trustable and honest supplier, but also the partner for our shoppers for Chinese wholesale Roll Forming Machinery - HJ-CPX400 Spring roll sheet production line – Hanjue Precision, The product will supply to all over the world, such as: Yemen , Serbia , Lesotho , Now we have a excellent team supplying specialist service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you. We also warmly welcome customers to visit our company and purchase our solutions.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.